Country of manufacture: Germany

Uses: Knife blades and very well for selective soaking

Uses : Knife blade with good hardness

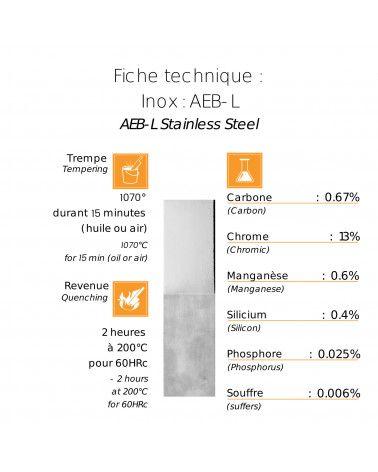

Chemical composition:

|

Carbon (C)

|

Chrome (Cr)

|

Manganese, Mn

|

Silicium (Si)

|

Phosphorus (P) max

|

Suffering (S) max

|

|

0.67%

|

13%

|

0.6%

|

0.4%

|

0.025%

|

0.006%

|

Thermal treatment:

- Trempe at 1070°C for 15 minutes then in oil or air

- Revenue for 2 hours at 200°C for 60HRc

AEB-L stainless steel is a renowned cutlery material for its outstanding quality and performance. It is widely used by cutlery craftsmen because of its specific properties.

AEB-L steel is a high-end stainless steel, specially designed to offer excellent corrosion resistance and good sharpness retention capacity.

A key feature of AEB-L steel is its relatively low carbon content, making it easier to sharpen and maintain. However, it still offers a high hardness, allowing to obtain a lasting and precise edge. In addition, the presence of chromium gives AEB-L steel increased corrosion resistance, making it ideal for humid environments.

AEB-L steel is also appreciated for its tenacity, i.e. its ability to withstand deformation and breakage. This makes it a reliable choice for knives for intensive uses.

Cutlery also appreciate the ease with which AEB-L steel can be worked. It is malleable and allows artisans to obtain complex shapes and precise finishes. In addition, it can be polished to obtain a smooth and aesthetically attractive surface.

Dimensions possible on order:

Max length: 10 to 600 mm

Width: 30, 40, 50, 75, 100 and 150 mm

Thickness: 3 or 4 mm